Aws Cwi Fundamentals Explained

Table of ContentsAws Cwi - An OverviewIndicators on Aws Cwi You Need To KnowAws Cwi Things To Know Before You BuySome Of Aws CwiThe 10-Minute Rule for Aws Cwi

Have you ever before took into consideration an occupation as a welding examiner? A welding examination qualification is not only a fantastic achievement, it validates your capabilities in the welding sector.

Ending Up Being a Licensed Welding Assessor reveals your commitment to expanding within the welding industry. This certification is one that must not and will certainly not be forgotten! As a CWI, you'll have the ability to benefit from a variety of various opportunities amongst market experts.

Certified Weld Inspectors are an incredibly valuable and valuable property for steel producers. Their visibility is rather valuable for any company hiring the producers that bring them on board. As you might know, welding is just one of one of the most complex solutions within the steel manufacture sector. The outcome of every welding project is highly dependent upon individual welder ability.

Aws Cwi for Beginners

There's no question that CWIs help to copyright higher degrees of uniformity and high quality to the welding divisions they manage. This article offers a brief review of the primary advantages of collaborating with a metal construction business that utilizes certified weld examiners. It's not surprising that a lot of prominent industries will need you to hire certified welding examiners to oversee welding.

Licensed welding inspectors have years of experience and hence, they recognize the subtleties of conformity with welding codes. Adhering to the welding process, CWIs can carry out a collection of test to check the high quality of a weld, including visual inspection, warmth treatment and a hydrostatic examination. Welding Inspection Service. They can additionally make the appropriate modifications to the pre-weld preparation and the in-weld procedures as essential

An in-house licensed welding assessor will certainly be able to ensure that your project is customized to all the requirements of pertinent welding codes, guaranteeing its quality. Welding assessors can review welding procedure specifications, structure and welding strategies, devices calibration and welding materials. A welding assessors capability to provide welding treatment requirements provides the steel fabrication firm a substantial edge of the competitors, enabling producers to design welds that best match private components, rather of making use of reliable welds.

The Best Guide To Aws Cwi

As previously pointed out, a CWI is not just liable fore creating the procedures for the weld, yet also the quality-check testing procedures. https://www.tripadvisor.com/Profile/randycS7688GJ. Beyond that, welding assessors function to make certain that tools is properly prepped for the job and that welders have the ability to finish their welds with proficiency (Welding Inspection Company). A qualified welding examiner will have had years of experience, which a metal construction company can utilize to make sure stellar end results for all fabrication projects that entail welding

This is why it's vital to discover a welding firm with a knowledgeable and highly educated internal qualified welding examiner on team. Luckily, CAMM metals is such a service, so call us today if you have an approaching project that needs high quality custom-made welding! It's clear that a custom-made steel construction supplier with internal CWIs has dedicated to purchasing the quality of its welds.

In addition, some industries need CWIs to be associated with the production of components. In the end, CWIs presume rather a little bit of duty, yet their experience displays in the end product. Right Here at CAMM Metals, after the welding portion of the job is full, we provide lots of internal solutions. These services consist of weld evaluation with dye penetrant, acid cleaning and polishing of stainless steel welds.

For those clients who need licensed welds, we can accredit our welds to AWS D1.1 & AWS D1.6.

More About Aws Cwi

It's crucial to note that several companies don't always need welders to be licensed. The major distinction is that certified welders have actually composed records of their test outcomes and their efficiency is regularly monitored with regular assessment( s) being component of the performance record for each welder.

Before taking the test all PFS welders are educated, if required, in the actual welding process that they will be utilizing and they will certainly need to have a working expertise of the welding tools, welding consumable and the product to be bonded. Effectively passing one test will allow the welder to work with several sorts of fabrications however will not allow him to work with all sorts of construction as there are certification varies imposed for every examination arrangement.

Essential variables consist of however are not limited to product kind, consumable kind, product density and welding placement. and so on. After the welder has actually completed his test plate or pipeline the weld is inspected utilizing the following NDE processes: Aesthetic Assessment X-Ray Fluid Penetrant Screening Sometimes, the weld is additionally destructively tested.

The Best Strategy To Use For Aws Cwi

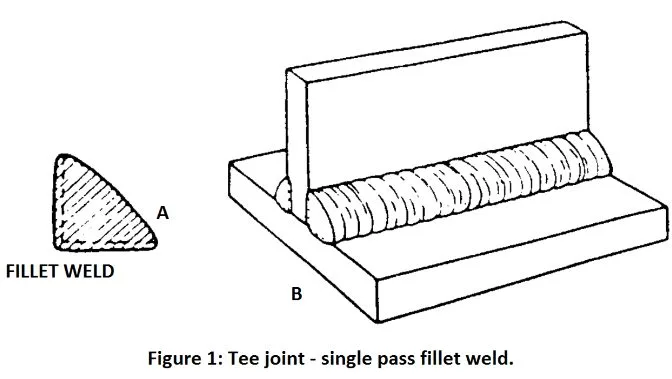

PFS achieves this making use of a continuity record that information all welds that a welder makes. If a welder does not utilize the welding procedure in a 6-month period, then they shall be requalified in that procedure. The benefits to utilizing a qualification system are many however the major benefits are: It verifies the ability of an individual to perform based on a certified welding procedure requirements (WPS) to produce an excellent weld.